Automotive Manufacturing Tooling

Carbide Products Inc. provides precision tooling and components for automotive manufacturing environments where consistency, repeatability, and production efficiency are essential. Our vast range of capabilities allow us to support all prototype and production needs.

Customers, Past and Present

Aftermarket

Edelbrock

Goodson Tools and Supplies

Competition Cams

Aisin USA

TI Automotive

O.E.M.

Toyota North America

Bridgestone

Dana Incorporated

Toyota

Robert Bosch Automotive

Engineering-Driven Automotive OEM Manufacturing Partner

What differentiates Carbide Products, Inc is our ability to operate as an engineering-focused manufacturing partner for automotive OEMs and Tiered suppliers. We are not simply a contract machine shop. We work directly with automotive engineering, program management, and procurement teams to improve manufacturability, reduce part cost, and ensure production reliability across the product lifecycle.

With 80 years of experience manufacturing precision components used in demanding automotive environments, we understand the importance of repeatability, tight tolerances, material performance, and on-time delivery within complex supply chains.

By combining engineering expertise with real-world machining experience, we help automotive OEM and Tiered suppliers reduce lead times, improve component performance, and maintain consistent production quality in high-precision applications.

Our Automotive Engineering Support Includes

Design for Manufacturability (DFM) and cost-down analysis

Tolerance stack-up review and optimization for production capability

Material selection consultation for wear resistance, strength, and durability

Precision process development and tooling strategy recommendations

Prototype, validation, and production ramp support

Continuous improvement and lifecycle cost reduction initiatives

Manufacturing problem solving and redesign assistance for legacy components

Production Benefits

Manufacturing efficiency

Reduced lead times

Process consistency

Durability

Applications

Production tooling

Wear components

Assembly tooling

Precision machined components

Materials

Tungsten carbide

Hardened tool steels

High-performance alloys

Engineering Plastics

Ceramics

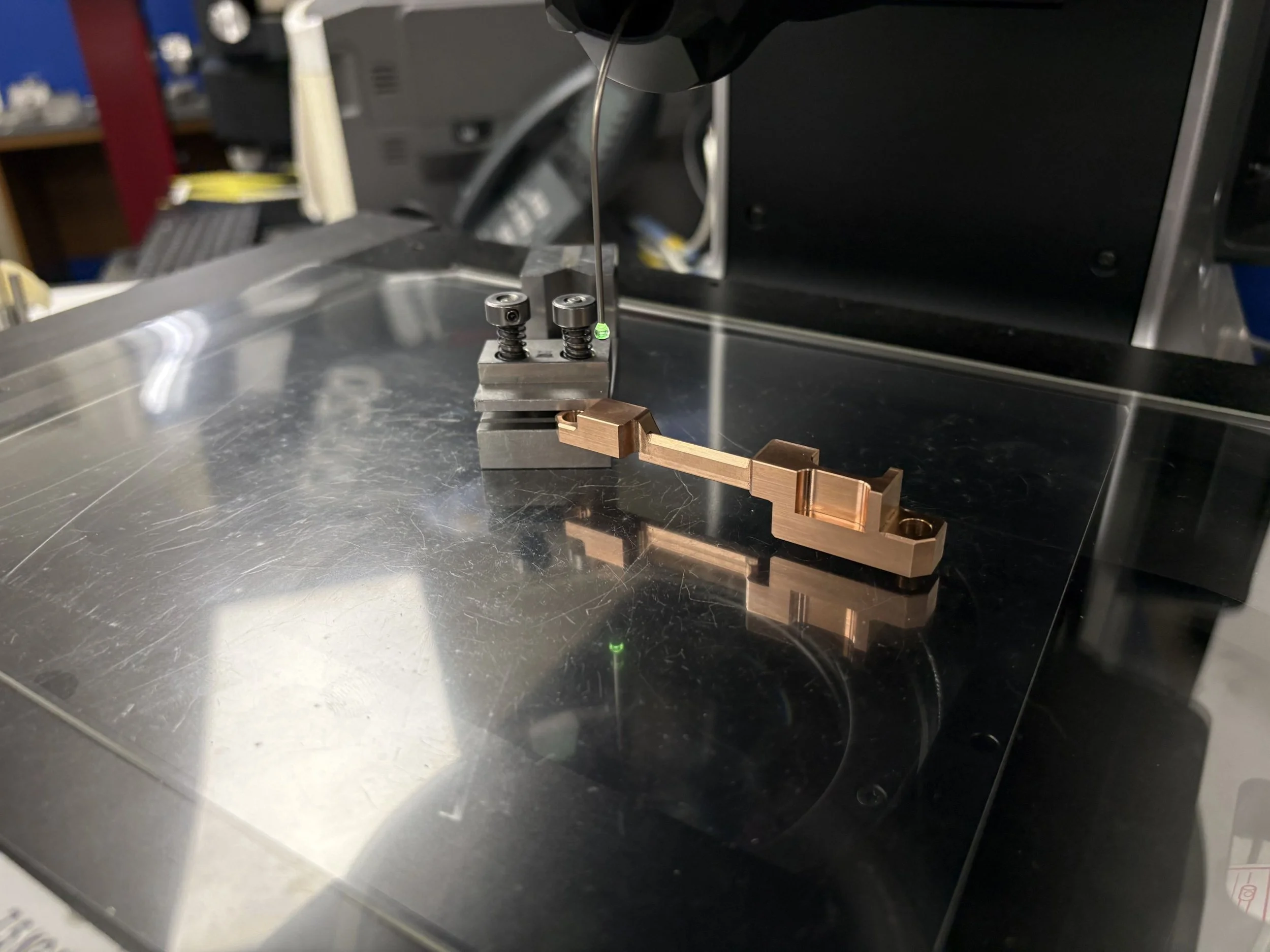

Copper and Bronze Alloys

Capabilities Under One Roof

CNC Milling

CNC Turning

CNC Grinding

EDM

Brazing

Heat Treat

Tolerances & Precision

We are capable of holding extremely tight tolerances depending on geometry and material requirements. These tolerances are often in the range of +/- 0.0002” (5 micron) for our grinding and EDM processes. More recently, thanks to our acquisition of some high end machining centers we are quickly getting down to +/- 0.0005” (+/- 0.012mm) for our mill and turning work centers.

Quality & Reliability

While our facility does not currently maintain formal certifications, quality control is embedded throughout our manufacturing process. We emphasize process consistency, experienced craftsmanship, and inspection discipline to ensure reliable performance in demanding aerospace applications.

To achieve the highest quality parts we have invested heavily in our inspection equipment. Each department has access to their own optical comparators, gauge pins, jo blocks, surface plates, and other metrology tools. Our milling department is equipped with their own Keyence optical inspection device allowing for easy setup validation and first part inspection and documentation.

Our inspection lab is equipped with a full range of gauge pins, jo blocks, micrometers, bore mics, and indicators. In addition to the traditional methods listed above our inspection lab is equipped with two state of the art Keyence inspection devices. Every inspection device that we have is serialized and subject to inspection and calibration on a regular basis.

Each job that goes through our shop is subject to inspection multiple times before process completion with final QC. Thanks to this process are able to create serialized and detailed inspection reports to ensure process traceability all the way to the material lot. Even if that level of inspection is not required for your parts we will record all final inspection data and store it on our server indefinitely because in our shop data is king.