EDM

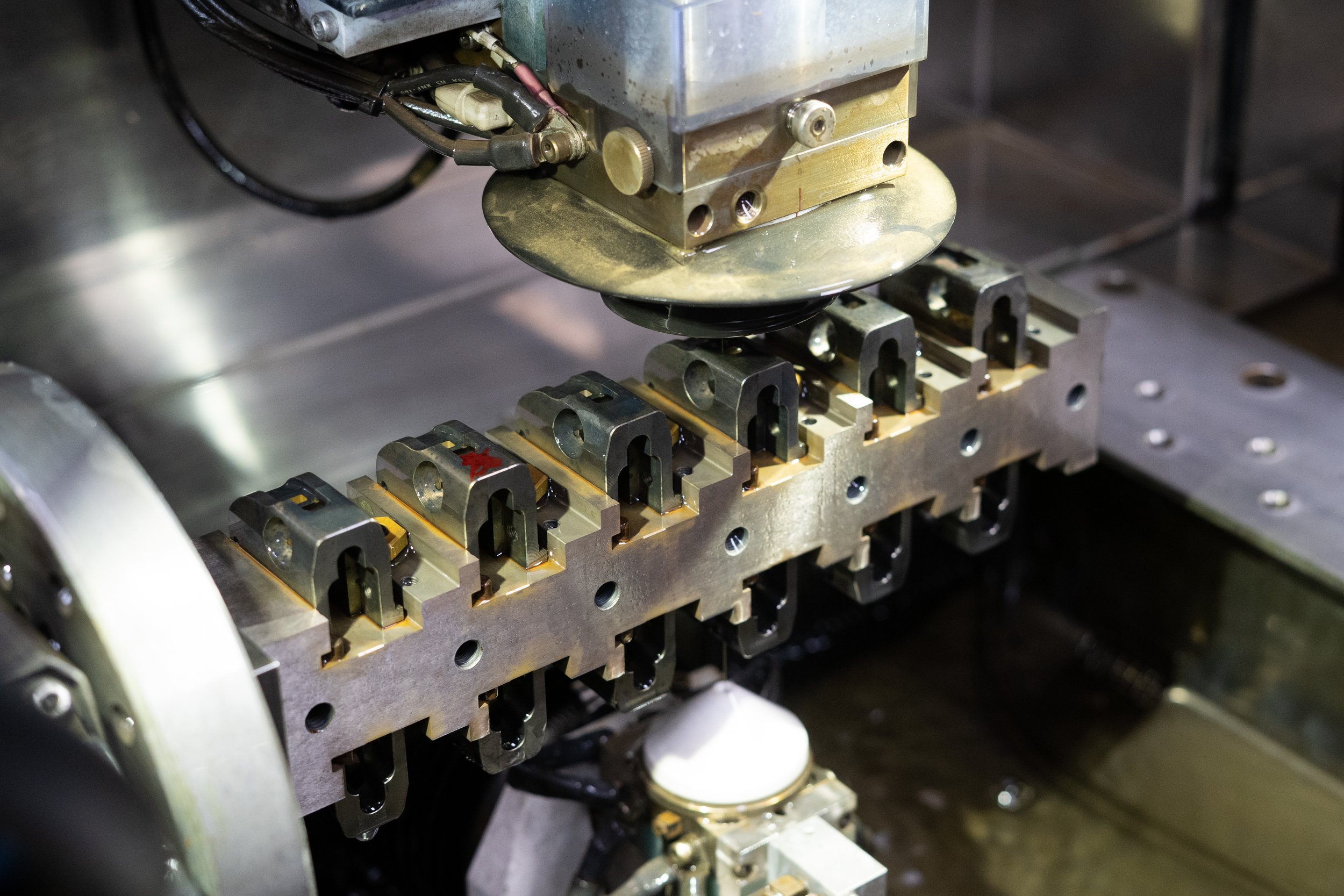

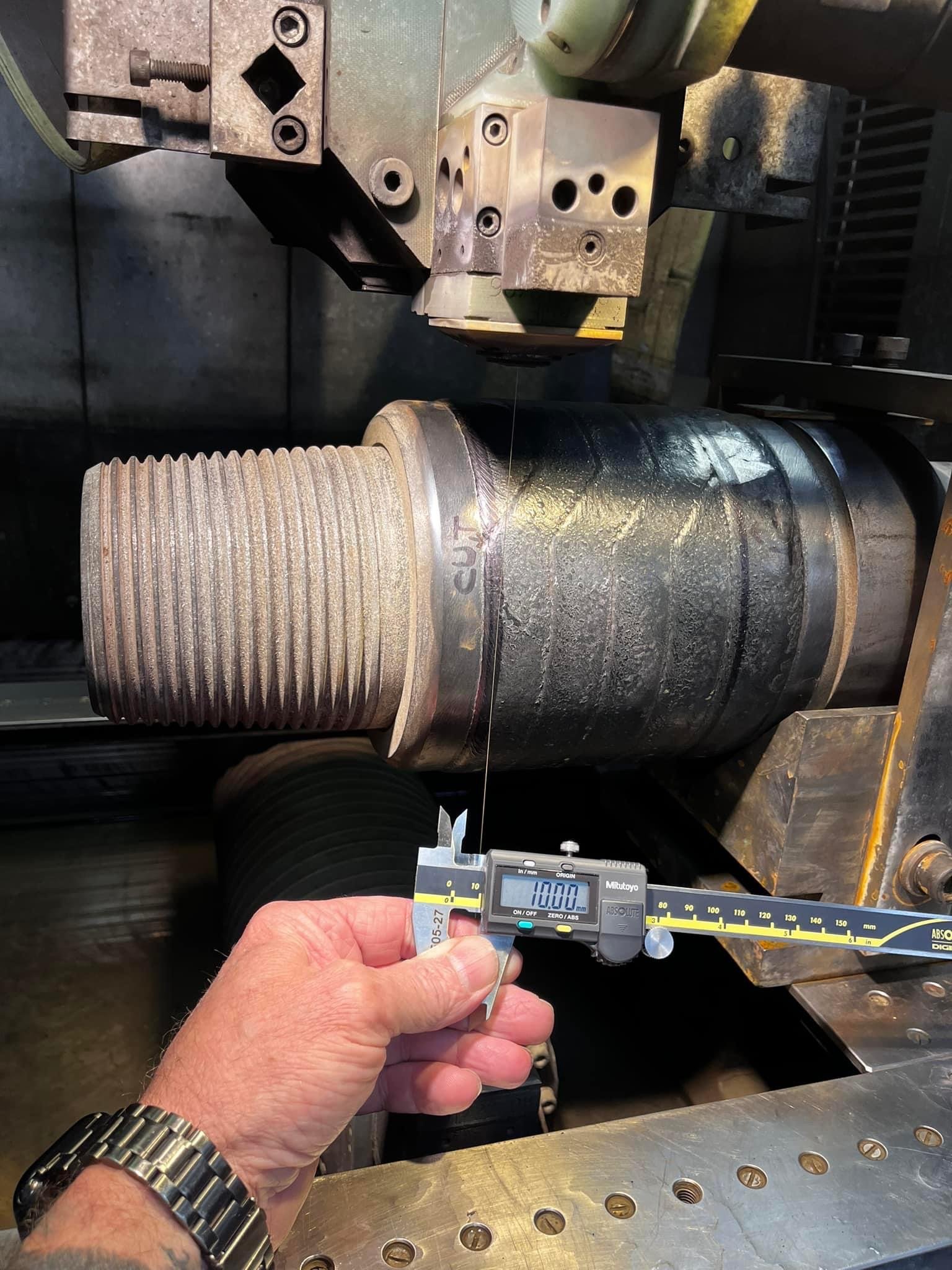

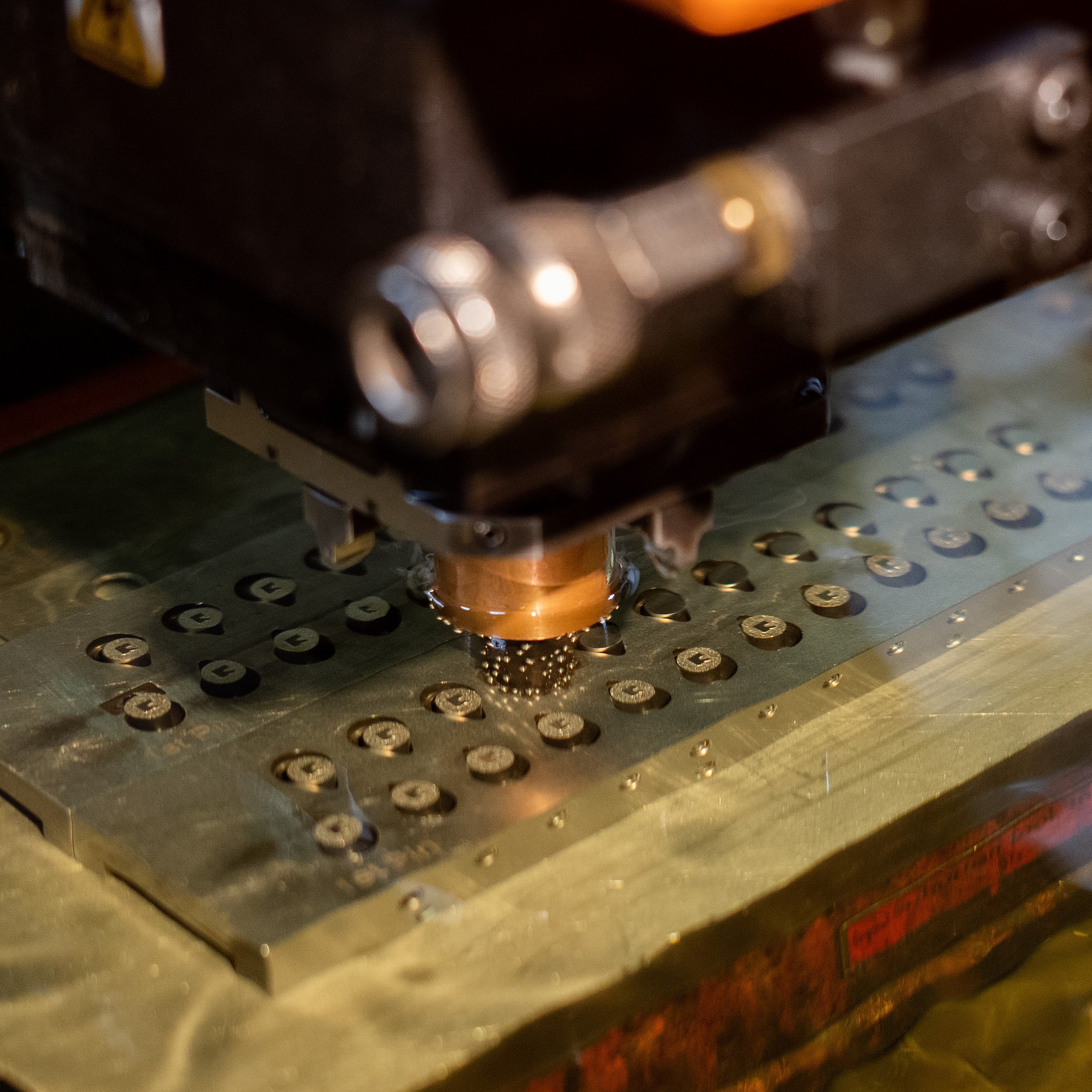

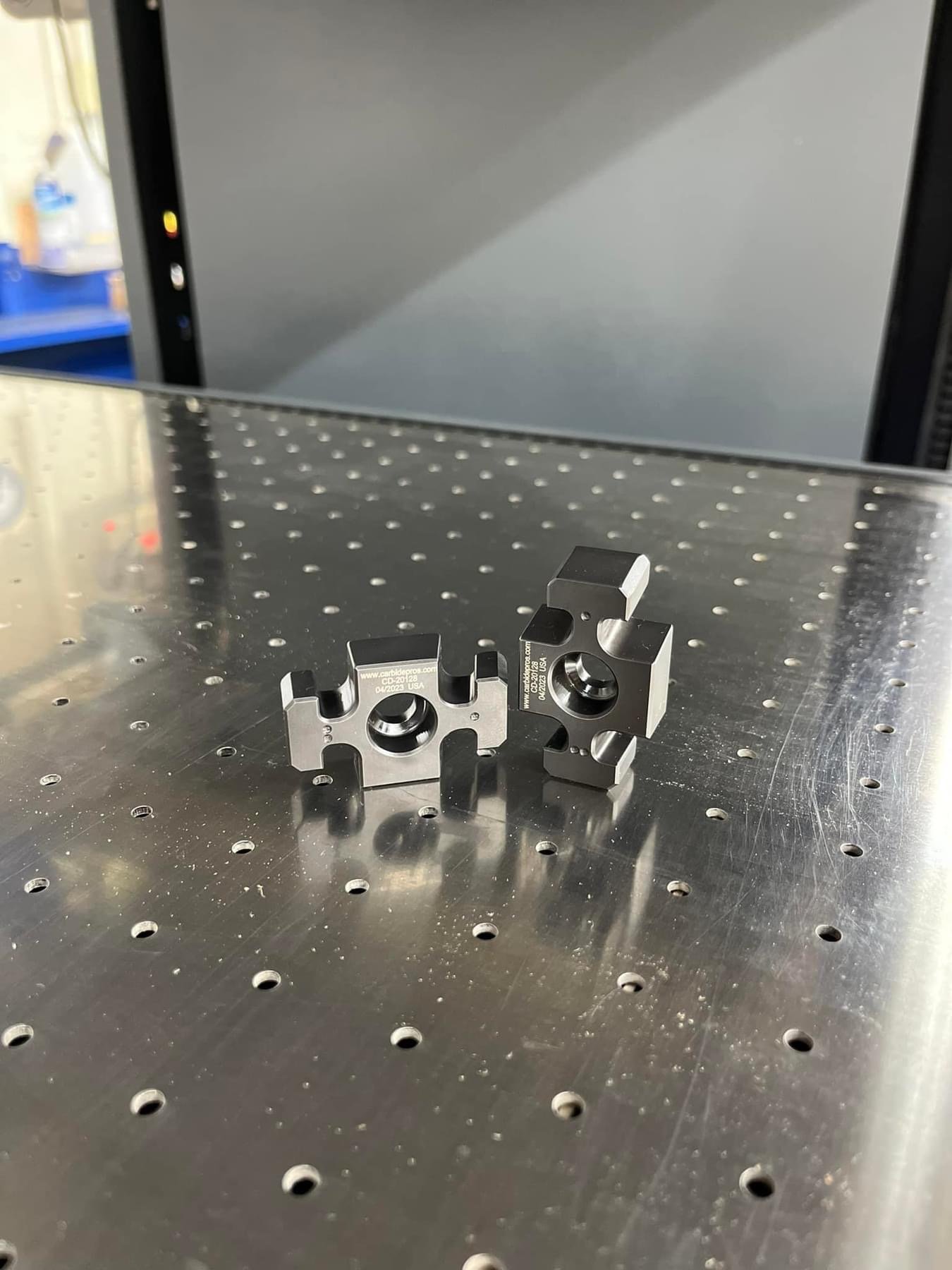

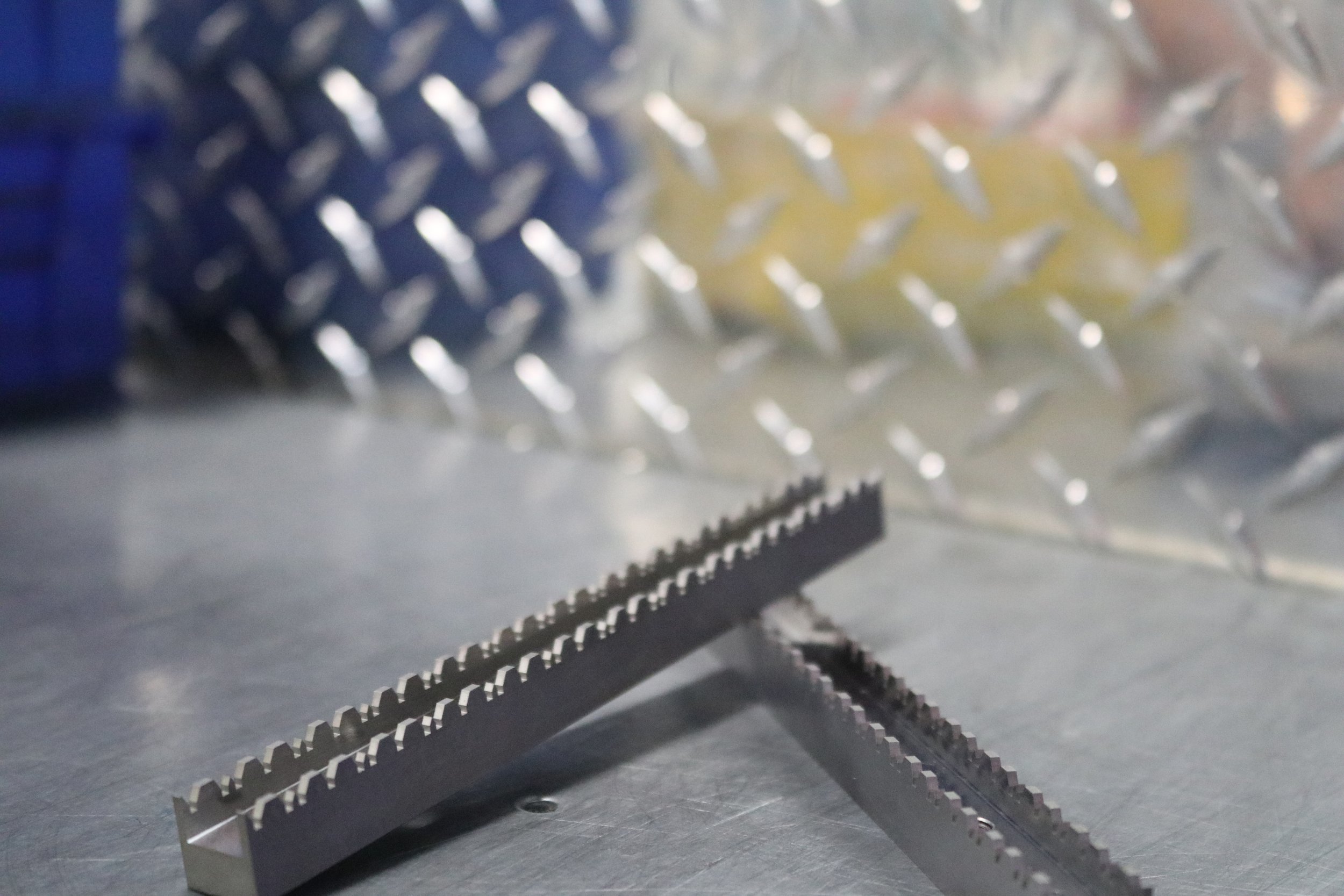

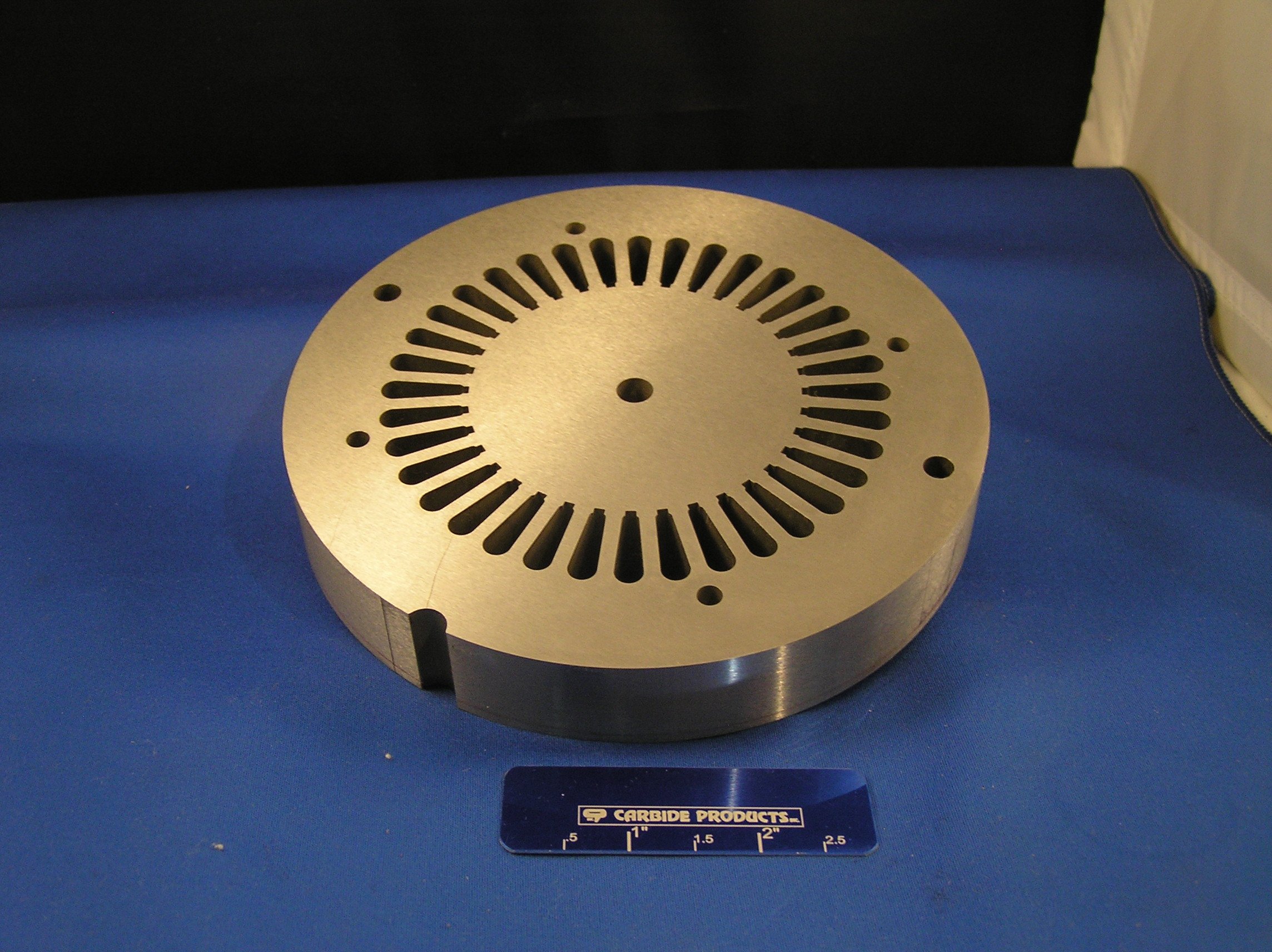

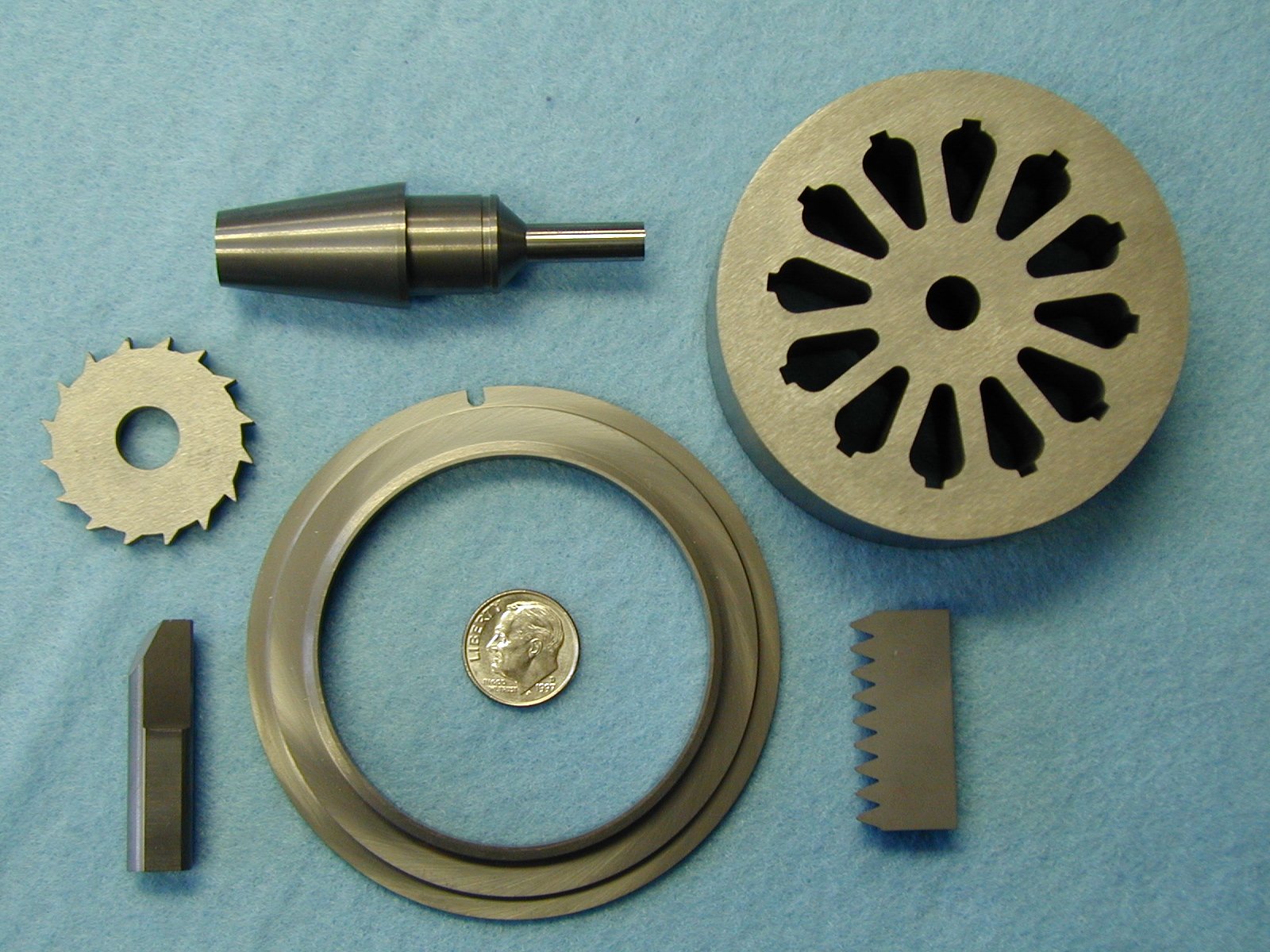

Wire EDM

Our EDM team has access to four wire EDM’s, offline part setup stations, manual tool-room vertical mill, tool-room lathes, second op lathe, drill presses, EMD hole popper, optical comparator and more. All of our machines are equipped with auto threading devices and often run 20 or more hour per day unattended.

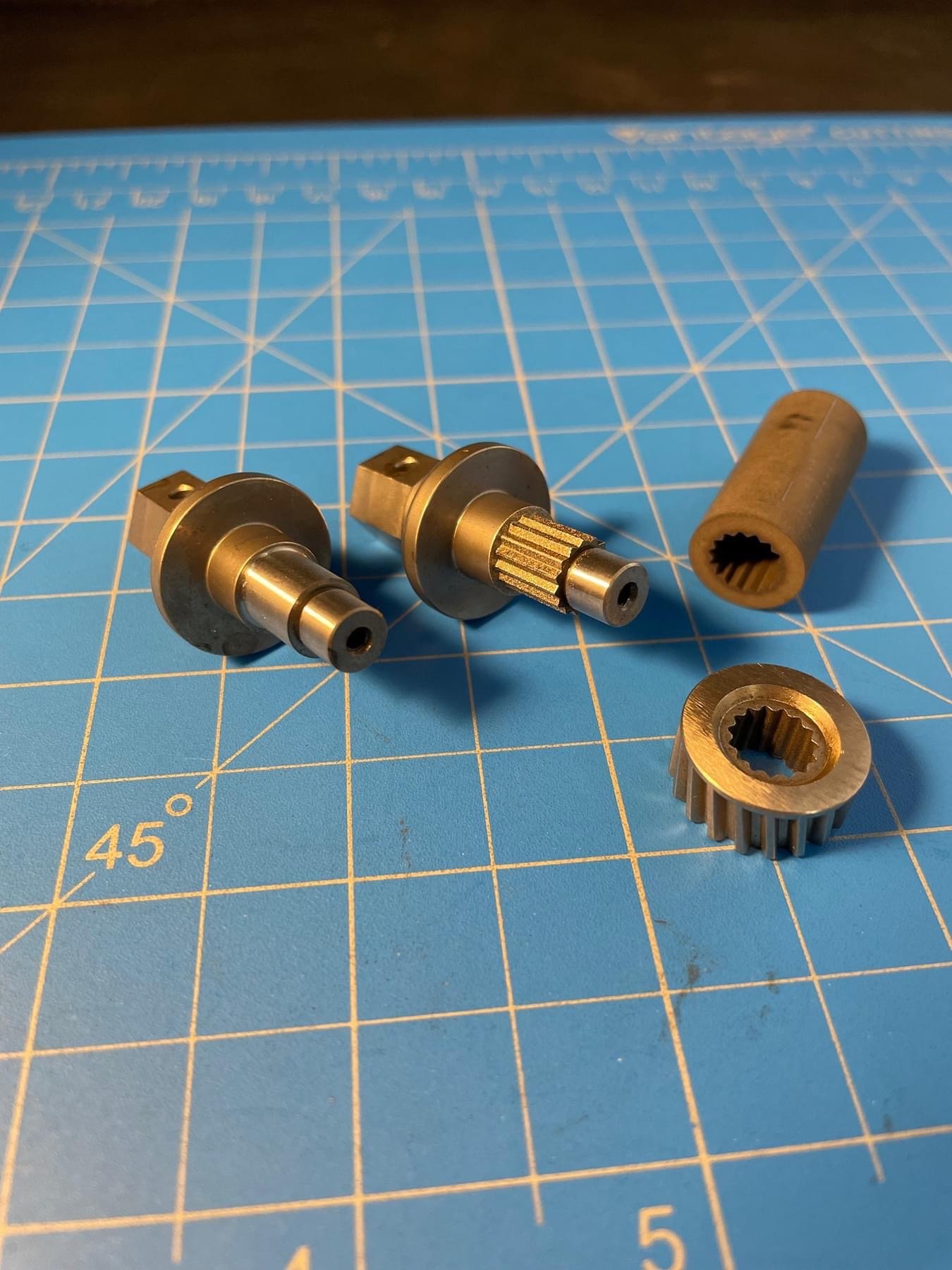

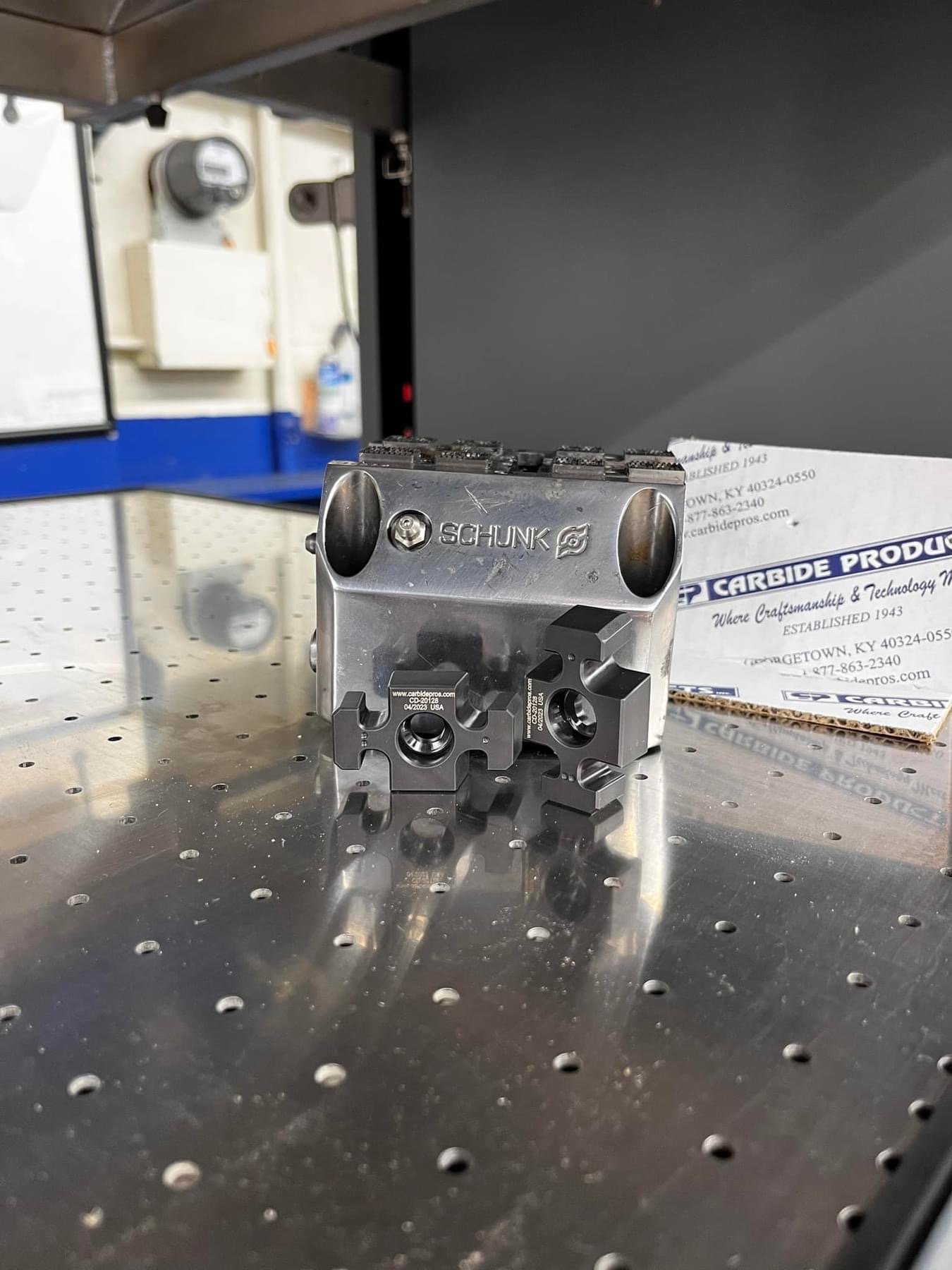

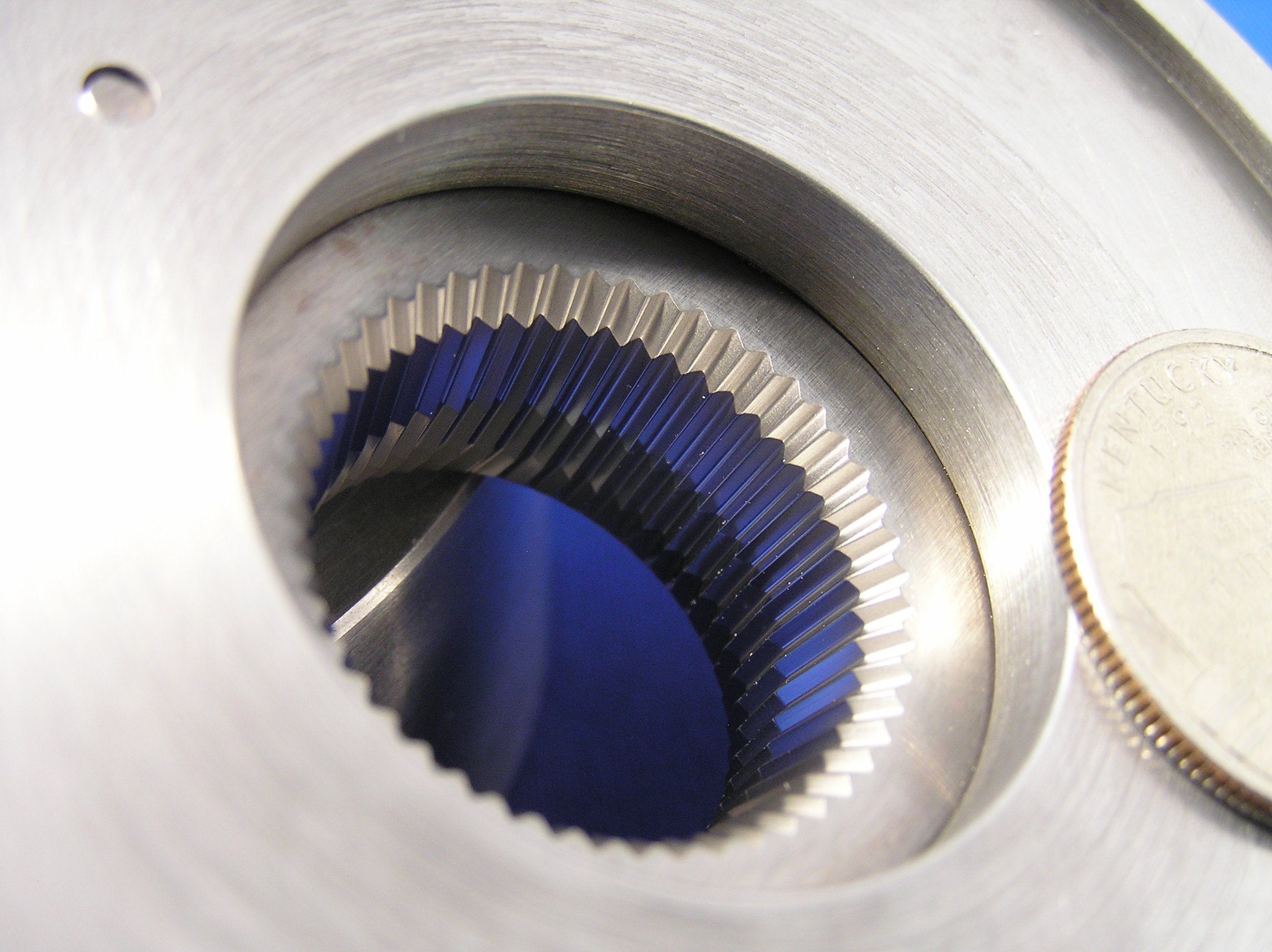

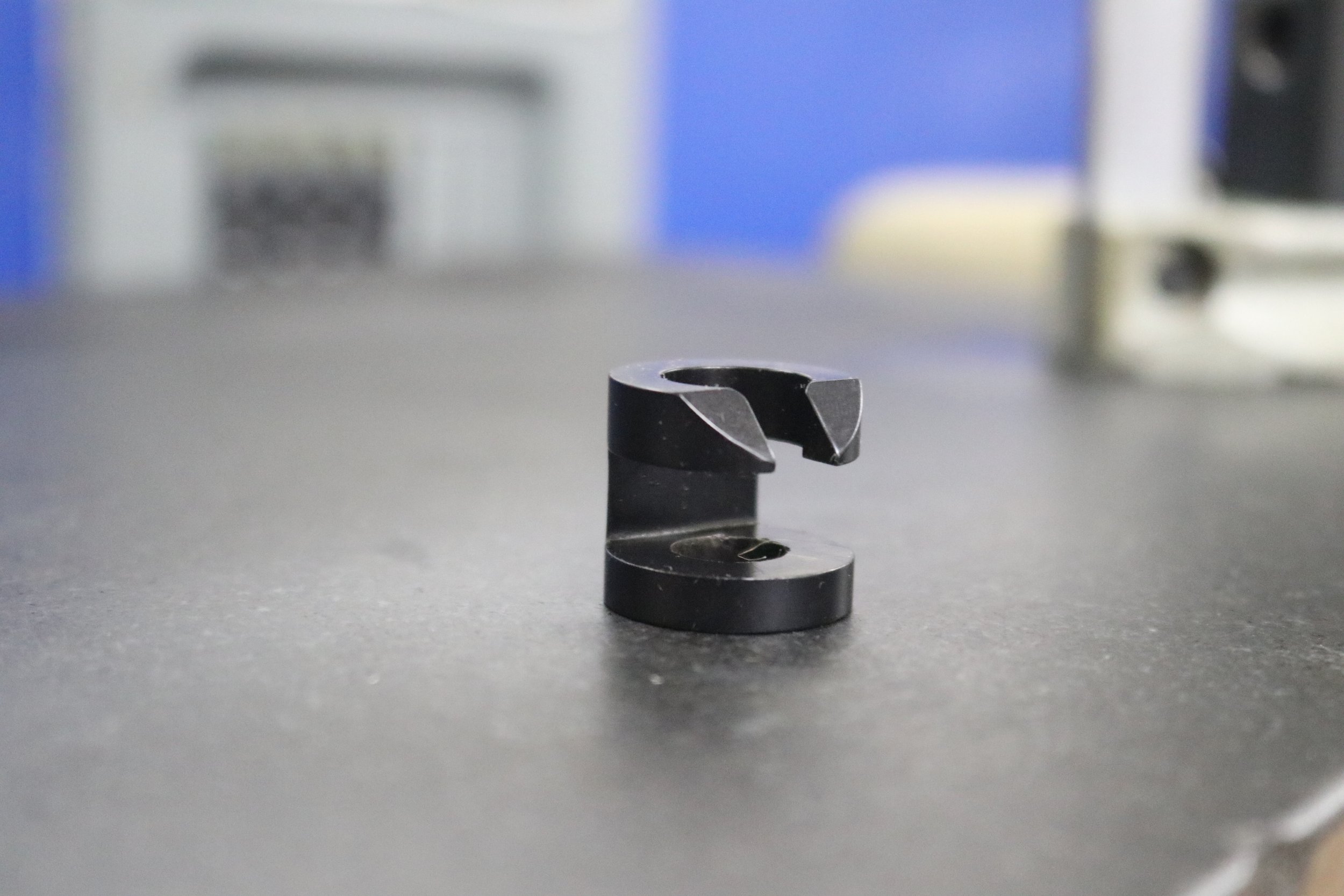

Sinker EDM

Our EDM team also has access to one traditional servo driven and two CNC sinker EDM’s, offline part setup stations, manual tool-room vertical mill, tool-room lathes, second op lathe, drill presses, EMD hole popper, optical comparator and more. All machines are equipped with Erowa spindle tooling and probing. Our largest machine is equipped with a 56 station electrode changer for complex and/or high volume jobs.